Bicycles before and during the 1980's were generally equipped with freewheel clusters that threaded onto the hub. The problem with this setup was that the freewheel during pedaling would lock on to the hub from the torque applied. Also the support for the axle on the freewheel side was under the spokes and this meant the axle could bend under load especially as cog sets grew from four to six cogs and upwards.

Cogs would also suffer from locking onto the freewheel as all the cogs would be screwed onto the freewheel. The larger cogs would suffer the highest torque and again this meant diassembly and creating custom gearing was difficult.

In worst cases the freewheel would need to be destroyed to remove it from the axle.

Francis Bes, a french inventor, registered the patent for the system that was later to be sold under the name Helicomatic at the end of the seventies.

The various patent applications can be found online at patent offices of various nations. I have included the French and U.S. patent applications on this website.

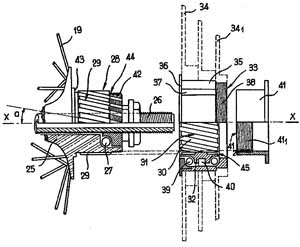

The aim of the system was to provide a solution that would enable the cyclist to remove the freewheel easily on the road and not lock permanently onto the hub from the torque applied by the cyclist. This was achieved by the unique and rather beautiful helical set of splines. The freewheel slid onto to hub easily and a very simple lockring could keep the system in place. The helical splines kept the freewheel on the hub during forward motion but would not tighten the freewheel with such tanacity onto the hub that it required force or special tools to remove it.

Only the smaller top cogs were screwed onto the freewheel, the larger cogs slid into vertical splines. This meant that diassembly of the cogs was much easier and custom gearing could be achieved more quickly.

The Helicomatic system also had the axle ball bearings in the hub under the outside edge of the freewheel rather than near the flange. This meant axles were better and more evenly supported.

Racing model hubs were fitted with 13 5/32" ball bearings on either side of axle. These bearings were much smaller than normal and are blamed for most of the technical problems with the hub. Accusations range from an 'exploding hub', the ball bearings having become 'shrapnel' damaging cup and cone to regular spoke breakage.

The Helicomatic system probably went into production at the factory of Maillard in Incheville around 1982. No records have been found so far of earlier production dates of bicycles that sport the Helicomatic system. The last record of bicycles with the system is 1988.

Before that time Maillard had already been taken over by the Geman Sachs corporation (1980). But most Helicomatic items still only mention the name Maillard (the hubs are always labelled, the freewheel commonly has no reference to the maker or type). The Maillard name had a good reputation and delivered many good bicycle components to the mayor bicycle manufacturers. Raleigh, Peugeot and Trek (to name some) all sold bicycles during the eighties with the Helicomatic system. Most bicycle companies only sold mid end bicycles with the Helicomatic system. Only in Peugeot catalogs high end bicycles with Helicomatic hubs and freewheels have been noted.

Most Helicomatic items were sold under the brand name (Sachs) Maillard, however some freewheels were sold under the brand name Atom and a very few Normandy hubs (Luxe Competition) used the Helicomatic system as well. Both these brand names were owned by Maillard (having taken over the Atom and Normandy companies during the fifties and sixties).

The Helicomatic system was used for racing, BMX and ATB/MTB bicycles (the latter are labelled 'Maillard Diabolo'). Freewheels for the race and MTB/ATB models are not interchangeable as the hole of the freewheel on the Diabolo hub is 33mm wide and the race model has a hole of 27mm. BMX bikes had both types of hub, the racing model and the diabolo (again 27mm and 33mm)

The freewheel assemblies came in 5 to eventually 8 speed variations.

A simple lightweight tool was supplied with every Helicomatic equipped bicycle to remove the lockring.

The lockring tool is now the most famous part of Helicomatic 'lore'. It could also be used as a bottle opener so no-one in the bicycle repair business would go thirsty ever again.

Eventually the design proved to be not a winner in the marketplace. When Francis Bes patented the Helicomatic system Shimano had already started production of their freehub design. Both systems had adressed the problems of the freewheel but the freehub design was better executed and marketed. Global economics also favoured japanese products. The only remaining advantage for Helicomatic being the ease with which the freewheel can be removed.

The european manufacturers followed suit. By the end of the eighties freehub was the commonest design implemented.

Sachs Bicycle components was acquired by SRAM in 1997 and they probably are now the legal owners of the Helicomatic patent and heritage.

Nowadays the main challenge for the Helicomatic rider is finding parts. I would suggest to all but the most fanatic about originality to stay away from Helicomatic or replace any Helicomatic hub with a model for which it is easier to source spare parts.

.jpg)

![]()